Manual or motorized: the two main categories of DITO SAMA dough sheeters

We offer a range of bakery dough sheeters, divided into two main categories: manual models and motorized models.

DITO SAMA manual bakery dough sheeters: performance and reliability for small establishments

Manual bakery dough sheeters are compact and easy to use, making them particularly suitable for small-scale bakeries and pastry shops.

At DITO SAMA, we offer a compact tabletop manual bakery dough sheeter, the LMP400, designed without compromise on quality, performance, or reliability. It features adjustable steel rollers. Our manual dough sheeter is easy to transport. Its 60 mm diameter rollers are coated with food-grade Teflon, and its removable stainless steel tables are designed for a working width of 400 mm. The rolling adjustment can be set to a thickness ranging from 0.1 to 27 mm, accommodating all your recipes.

Motorized bakery dough sheeters by DITO SAMA, ideal for large establishments and intensive use

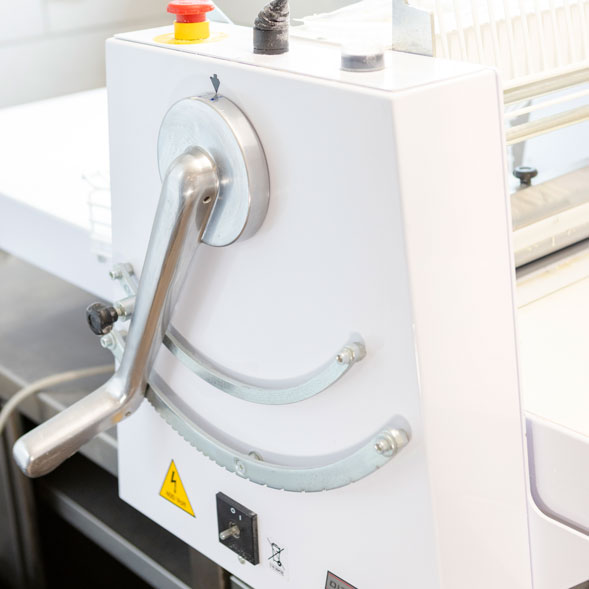

The motorized bakery dough sheeters, offering more power, are designed for bakery and dough production. The LMP500, LMP500BT, and LMP600BT models feature adjustable steel rollers, combining precise dough sheeting with faster operation. They can be equipped with a remote pedal for easy directional changes.

WHAT ARE THE KEY FEATURES OF DITO SAMA DOUGH SHEETERS?

Irrespective of their size and mode of operation, DITO SAMA dough sheeters come with shared features that reflect our commitment to quality and performance.

Irrespective of their size and mode of operation, DITO SAMA dough sheeters come with shared features that reflect our commitment to quality and performance.

Our bakery dough sheeters enable easy adjustment of dough thickness to meet your specific needs.

DITO SAMA bakery dough sheeters are designed for ergonomic, intuitive use, even for novice users. Optionally, motorized models can be equipped with a pedal to easily change the direction of rotation.

covering either parts and labor, depending on local legislation and local sales conditions.

Motorized DITO SAMA bakery dough sheeters are fitted with an industrial asynchronous motor, engineered to ensure durability and quiet operation.

The DITO SAMA bakery dough sheeter range is designed to work with various types of dough, including puff pastry, shortcrust pastry.

Our electric models come with circuit breakers and fuses. Different safety devices (safety microswitch, emergency stop button, automatic stop if grids reach a dangerous level) are implemented to ensure user and equipment safety.

Why choose a DITO SAMA bakery dough sheeter?

At DITO SAMA, we understand your profession, your needs, and your expectations. We are committed to providing you with bakery dough sheeters that simplify the daily routines of bakery and pastry professionals.

Furthermore, DITO SAMA has been designing equipment for foodservice professionals for almost 80 years, combining expertise and a deep understanding of the needs and expectations of restaurateurs. Our products are recognized for their performance, durability, and ease of use and maintenance, transforming the culinary experience.

With our bakery dough sheeters, you can be confident in preparing high-quality, consistent dough that ensures even baking, superior finished products, and satisfied customers. Additionally, you'll save time in the kitchen by efficiently and rapidly working the dough. This translates into time and energy savings during recipe preparation.

Choosing a DITO SAMA bakery dough sheeter means unleashing your creativity. You'll be able to prepare all your dough recipes, both current and future, thanks to the versatility of our machines suitable for all types of dough. Create puff pastry or shortcrust pastry; easily adjust the dough thickness to meet your specific needs, evolve your recipes, and surprise your customers!

HOW TO CHOOSE YOUR BAKERY DOUGH SHEETER?

The bakery dough sheeter is an essential tool for professional bakers. It enables the efficient, rapid, and consistent rolling and flattening of various types of dough. However, with the of models available on the market, selecting the right bakery dough sheeter for your establishment can be challenging. The solution: meticulously consider each selection criterion.

How to Maintain Your DITO SAMA Bakery Dough Sheeter?

The DITO SAMA bakery dough sheeter is a robust and high-quality piece of equipment designed to support your operations over the long term. However, this doesn't mean you should neglect regular maintenance, which ensures optimal functionality and extended lifespan. To perfectly maintain your DITO SAMA dough sheeter, follow our advice.

01.

Clean your DITO SAMA bakery dough sheeter regularly

Regular cleaning will prevent the buildup of dough and flour residues in your DITO SAMA bakery dough sheeter. Simply use a damp cloth to clean the cylinders and worktables—avoid using abrasive sponges that could damage them—right after using your dough sheeter. Also, steer clear of chemical products or cleaners that could harm the surface of your equipment.

02.

Lubricate your DITO SAMA bakery dough sheeter

With numerous moving parts, the bakery dough sheeter needs regular lubrication to ensure optimal performance. Just use food-grade oil from your kitchen to lubricate the cylinders and gears. Be sure to avoid any petroleum-based lubricants, as they could contaminate your dough. Lubricating your dough sheeter has to be done by a technician.

03.

Conduct regular inspection of your DITO SAMA bakery dough sheeter parts

Regularly inspecting the parts of your DITO SAMA bakery dough sheeter will help ensure they're in good working condition. Check the belts, gears, and bearings for any misalignment or defects. Any play in the moving parts, indicative of wear or damage, should prompt you to adjust or replace the relevant parts. You should call on a technician to conduct a regular inspection.

04.

Promptly replace worn or damaged parts on your DITO SAMA bakery dough sheeter

Are some parts of your DITO SAMA bakery dough sheeter damaged or worn? Replace them as soon as possible. Spare parts for your equipment are readily available from DITO SAMA. For your security, the replacement parts must be carried out by a maintenance specialist.

05.

Refer to and keep your DITO SAMA bakery dough sheeter's user manual

Don't forget to consult your equipment's user manual: even if it's intuitive to use, you'll find instructions for maintenance and upkeep.

If you encounter any issues with your DITO SAMA dough sheeter, seek assistance from a qualified professional to perform the necessary repairs.

01.

Clean your DITO SAMA bakery dough sheeter regularly

Regular cleaning will prevent the buildup of dough and flour residues in your DITO SAMA bakery dough sheeter. Simply use a damp cloth to clean the cylinders and worktables—avoid using abrasive sponges that could damage them—right after using your dough sheeter. Also, steer clear of chemical products or cleaners that could harm the surface of your equipment.

02.

Lubricate your DITO SAMA bakery dough sheeter

With numerous moving parts, the bakery dough sheeter needs regular lubrication to ensure optimal performance. Just use food-grade oil from your kitchen to lubricate the cylinders and gears. Be sure to avoid any petroleum-based lubricants, as they could contaminate your dough. Lubricating your dough sheeter has to be done by a technician.

03.

Conduct regular inspection of your DITO SAMA bakery dough sheeter parts

Regularly inspecting the parts of your DITO SAMA bakery dough sheeter will help ensure they're in good working condition. Check the belts, gears, and bearings for any misalignment or defects. Any play in the moving parts, indicative of wear or damage, should prompt you to adjust or replace the relevant parts. You should call on a technician to conduct a regular inspection.

04.

Promptly replace worn or damaged parts on your DITO SAMA bakery dough sheeter

Are some parts of your DITO SAMA bakery dough sheeter damaged or worn? Replace them as soon as possible. Spare parts for your equipment are readily available from DITO SAMA. For your security, the replacement parts must be carried out by a maintenance specialist.

05.

Refer to and keep your DITO SAMA bakery dough sheeter's user manual

Don't forget to consult your equipment's user manual: even if it's intuitive to use, you'll find instructions for maintenance and upkeep.

If you encounter any issues with your DITO SAMA dough sheeter, seek assistance from a qualified professional to perform the necessary repairs.

Frequently asked questions about DITO SAMA bakery dough sheeters

The maximum working width of the cylinders depends on the model of DITO SAMA bakery dough sheeter being used. Our various models can offer a working width of 400 mm (for the LMP400), 500 mm (for the LMP500 and LMP500BT), or 600 mm (for the LMP600BT).

Cleaning the cylinders of the DITO SAMA dough sheeter should be done simply using a soft damp cloth. Never use an abrasive sponge or harsh cleaning product, as they could damage the cylinders.

The dough thickness is adjusted by changing the gap between the sheeter's cylinders, using a simple and intuitive control. Depending on the models, the dough thickness can be adjusted from 0.1 mm to 28 or 34 mm, depending on the specific model.

For nearly 80 years, DITO SAMA has been designing, manufacturing, and marketing the widest range of professional kitchen equipment in the market. Over the years,the brand has established a strong reputation for robustness, innovation, andreliability among restaurateurs.

Their products, including dough sheeters, are known for their quality, durability, and carefully crafted design tailored to meet the specific demands of the demanding professional culinary world.

Choosing a DITO SAMA dough sheeter, whether for a bakery, pastry shop or any establishment focused on dough-based products, means choosing quality, performance, and safety. It's also a way to gain a competitive advantage.

Interested in bakery dough sheeters?

Contact us to learn more about our professional bakery dough sheeters, request a personalized quote, or place your order.

Contact Us